- PCL Batteries

- Drive Couplings

- Lubrication

- Serious Cleaning

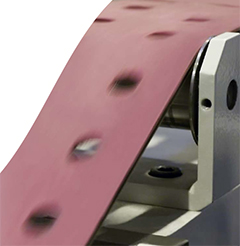

PLC Batteries

Maintenance frequency: Change yearly

Almost like clockwork, someone calls in a panic after a 3 day weekend or long holiday and says their machine will not run. Often times, this is a PLC related issue because the backup battery was on its last leg and the long weekend pushed it over its useful life. Not good since your customers are expecting you to deliver.With the New Year, why not make a new PLC battery part of your yearly machine check? The small cost of a battery will pay dividends to your bottom line long term.

Not sure what to do? Give us a call, we can help.

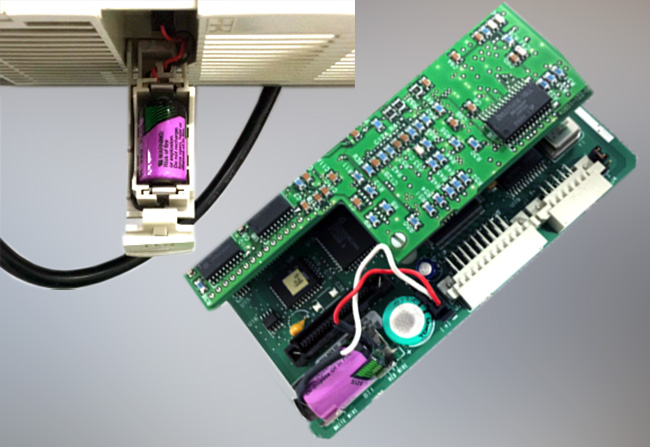

Drive Couplings

Inspection interval: Every 6 Months

Lubrication: Per instruction manual

What to look for: Any rotational play when manipulated

Often times drive couplings are overlooked until the point where customers call and complain about marginal box quality. And if regular box checks are not being performed, that can be an expensive problem to correct. Print moves around on the board and slots can follow in their own random pattern.Do your maintenance people know what to look for when couplings start to wear? How often are couplings to be inspected? Does it take a long time to inspect these items? Not sure what to do? Fortunately, we are here to help and provide you the solutions to these issues.

Give us a call.

EMBA 140, 160, 170 Vacuum Belt Drive Shaft Coupling

McKinley Constant Mesh Coupling

Maintenance: Lubrication

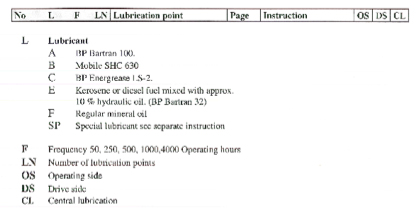

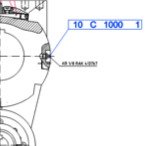

We have all been in the situation where scheduled maintenance is required, but gets put off for production reasons. Maybe it’s a weekly service where maintenance goes in and greases the machine. The service gets done, but was it performed properly? Are the motions of maintenance "same ol same ol", or is it performed to manufactures specs? What does manufacture’s spec mean? Pictured are 2 examples that can be found in the EMBA 170 parts books.

In the first example (above) we can see that this tab head is item 10, requires BP Energrease LS-2 (designated by the letter C), every 1000 running hours, and there is only 1 lubrication point.

In this example, we can see 2 callouts. The top one is a break-in oil change after 50 running hours. After that, the oil changes are every 1000 running hours.

If we hypothetically calculate this with a 6 day work week, then 2-10 hour shifts per day = 60 running hours (provided the machine runs all 20 hours per day). For the both examples, this would need lubricated every 16.667 weeks or 4 months at the example rate given. This is great, but keep in mind that some items need shift to shift attention such as slotting shafts, and linear setting shafts. These items can be found in the instruction manual.

So, how do you know when these time frames are approaching? EMBA utilizes a run timer in the electrical panel so maintenance can plan the appropriate service at the correct time intervals. OEM maintenance schedule, while not wasting valuable resources, and saving money in the long run….what could be better than that?

Still have questions, give us a call.

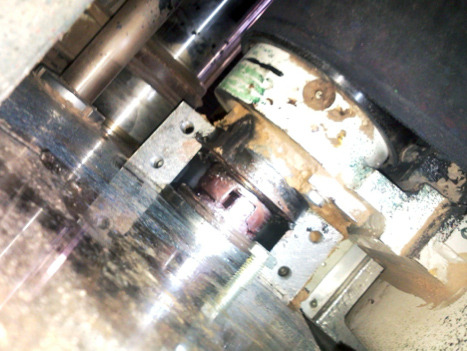

Time for some Serious Cleaning

When was your machine most recently cleaned, and problems addressed? For some, the answer is elusive, others can produce documentation as to when, what, and who performed maintenance or a repair. The really good ones, can tell you in advance what is due, have parts on the shelf and know what days the machine is going down for repair.Poor housekeeping can and often leads to poor machinery performance, increased wear to drive line components, and lower productivity. Typically the vacuum belt and vacuum table suffer the most from sloppy or non-existent cleaning. Below is an example of some poor housekeeping.

This example shows how poor housekeeping can affect a machine. All of the vacuum dampers were out of “time” and the vacuum tunnel was so full of debris, that vacuum was not present in various places on the table. This customer had issues with sheet skew and registration. Don’t let your machine get behind the 8 ball. Be proactive about service and housekeeping.We can help, give us a call.