-

EMBA Machines

- EMBA 175 QS Ultima™

- EMBA 215 QS Ultima™

- EMBA 245 QS Ultima™

EMBA Machines

EMBA machines are acknowledged for extremely high productivity and box quality thanks to the outstanding short set up times and high running speeds with consistent and repeatable performance in the entire product range. The open access top printing machines provides superior and easy survey of the machine operation which together with the smart and logical operators interface make the EMBA machines extremely simple and quick learn and operate.

EMBA MODEL

|

BOARD SIZE |

SKIP FEED

|

MAX SPEED |

||

MIN |

MAX |

SH./MIN. |

SH./HR. |

||

175 QS Ultima™ |

200 x 400 |

600 x 1700 |

800 x 1700 |

500 |

30,000 |

215 QS Ultima™ |

210 x 460 |

750 x 2150 |

900 x 2150 |

420 |

25,200 |

245 QS Ultima™ |

280 x 600 |

1050 x 2450 |

1400 x 2450 |

300 |

18,000 |

The intelligent way to speed production

In the capital-intensive converting industry, speed is good and intelligence even better. However, for long-term commercial success, flexibility is the key. The industry’s substantial equipment costs make high capacity utilization essential. The speed, intelligence and flexibility of the EMBA 245 QS Ultima™ enable rapid and precise adjustment to the latest market trends and demands. Whatever the size or grade of corrugated board to be converted, however advanced the print requirement, the EMBA 245 QS Ultima™ will handle it superbly. This means satisfied customers with optimized machine utilization.Minimal set-up time

The EMBA 245 QS Ultima™ is designed for maximum production output with the shortest set-up time, making it ideal for short order sizes required by just-in-time demands. Combining advanced digital communication with an exceptionally user-friendly operator interface, the highly automated and servo controlled EMBA 245 QS Ultima™ cuts setting time to a minimum. Though easy to use, the EMBA Operator Interface is highly sophisticated, permitting precision setting of operating parameters. The machine can easily be set for 50 or more separate orders during a single eight-hour shift! The Operator Interface provides online adjustment of machine settings, comprehensive process monitoring and access to a database of 100,000 repeat orders. This is the sort of speed and flexibility that guarantees success. It’s fast, intelligent and flexible.

High-speed production

The EMBA 245 QS Ultima™ is fast moving, as well as fast thinking. With its unique vacuum transport system providing converting speeds of up to five sheets per second, it gives the highest productivity on the market.

Intelligent design... One of the most technically advanced machine platforms on the market, the EMBA 245 QS Ultima™’s short set-up times, high running speeds and consistent product quality make it the intelligent choice. The user-friendly Operator Interface, digital control servo-driven technology and advanced communication interface enables integration into a broader interactive network. This opens up a wide range of communication possibilities.

Smart communications

A direct link between the EMBA 245 QS Ultima™ and the factory’s production control system enables an exchange of data on queued orders, job schedules and production statistics via the EmBase interface. An interactive network allows access to EMBA’s online support, securing the entire production process. Whatever the geographical location, EMBA will be right there, via a secure Internet link.

Designed for sustainable evolution

Transforming a vision into industrial excellence is an organic process – like creating a pearl from a grain of sand. The EMBA 245 QS Ultima™ features a whole range of technical improvements that enhance productivity and product quality. A powerful reason to invest. But, like the oyster, its true value – though less obvious – is much greater. The industrial climate is constantly evolving. Success has always been about transforming challenges into opportunities: for industry, these challenges now include sustainability, energy efficiency, environmental impact and occupational safety. The pearl at the heart of the EMBA 245 QS Ultima™ is EMBA’s evolutionary Non-Crush Converting™ technology platform, designed to evolve with industry’s needs. Technical innovation and commercial development in perfect harmony. The EMBA 245 QS Ultima™ is future-ready.

Lean

Intelligent and fully-integrated, EMBA 245 QS Ultima™ servo technology continuously monitors and optimizes all operational parameters. This intelligent machine platform, with its advanced servo motor technology, minimizes material costs, reduces waste and energy costs, all vital factors for enhanced profit. EMBA 245 QS Ultima™ technology offers the lowest operational costs on the market.

- Cost-efficient: minimal waste and optimal board utilization for consistent raw material cost savings.

- Sustainable: strong focus on reduced energy and raw material consumption.

- Ergonomic: designed to be easy to use with enhanced operator safety.

Clean

The EMBA 245 QS Ultima™ is a clean machine. Its advanced technology cuts waste, effluents, emissions and other factors affecting environmental impact. A reversible ink pump and high-efficiency washing system reduces ink loss, water consumption and also waste ink treatment costs.

Safe

The user-friendly EMBA 245 QS Ultima™ combines ergonomic design with same-side access, enabling operators to maintain visual contact at all times. Enhanced operator safety is provided by a comprehensive interlocking safety system and elimination of the feed roller inlet nip point, marking a major safety improvement for feed unit operators. Modular design, top-access, safety systems and Non-Crush Converting™ technology ensures the EMBA 245 QS Ultima™ is safe and easy to operate.

EMBA 245 QS Ultima™ - The online inline machine

The fully integrated servo platform and modular design of the EMBA 245 QS Ultima™ offers outstanding capacity and flexibility. Fast and cost-efficient, the EMBA 245 QS Ultima™ can produce all types of boxes, from the simplest brown box to the highest quality printing and most complex die-cut formats. The EMBA Operator Interface provides comprehensive control throughout the entire converting process, offering optional interfacing with auxiliary equipment, from pre-feeder to bundling machine and palletizer.From the high-speed non-crush Ultima Feeder™ to the efficient Counter-Stacker unit, the EMBA 245 QS Ultima™ is optimized for consistent high productivity. High paper utilization, low energy consumption, extreme reliability, minimal waste generation and self-diagnostic capability make it exceptionally cost efficient. And the EMBA Comfort program is your assurance that the EMBA 245 QS Ultima™ will continue to be an excellent investment, throughout its entire life cycle.

Operator Interface The Operator Interface is the link between the operator and the machine, consisting of monitor and keyboard controls for quick and simple use. The easy to learn and use software makes the operation of the machine extremely user-friendly, a must for real Quick-Set™ setting of new orders or repeat orders instantly downloaded from the article database. During production, the operator will supervise and control the entire machine through the interactive Operator Interface. Support menus for operation, service and maintenance instructions, together with logging and diagnostics of machine data are also included, providing an intelligence platform for comprehensive machine and production management. The Operator Interface optionally also features communication access to factory production control network systems, auxiliary equipment and VPN-internet connection for remote EMBA online support.

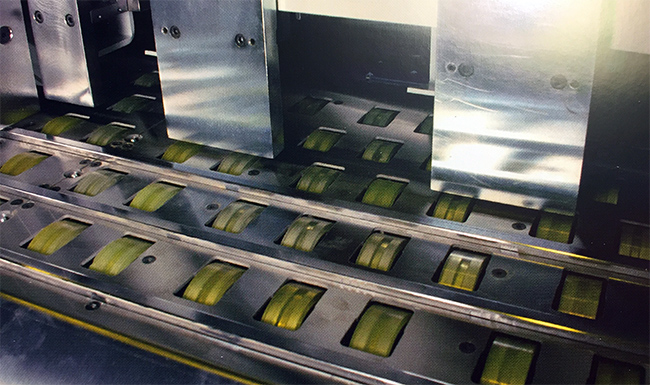

Ultima Feeder TM The EMBA Ultima Feeder™ is the revolutionary innovation for non-crush feeding of sheets without a feed roller, making true Non-Crush Converting™ possible. Advanced servo and vacuum design solutions ensure high-speed performance with superior feed register for all paper qualities and sheet sizes.

QSD Die-Cutter High speed die-cutting of sheets with complex layouts for all sizes and corrugated board configurations is easily accomplished in the sturdy Quick- Set™ Die-Cutting unit. An optional waste evacuation unit is available for the toughest jobs, and pre-mounting of tools on the tool cylinder in the standby position makes the unit fully Quick-Set™ . For complex internal die-cutting requirements there is an optional bottom Die-Cutting unit available with an integral waste evacuation unit and quick-change tool-mounting system.

Magna VSC Slotter The Magna VSC-Vacuum Slotting Creasing unit with the unique vacuum transport of sheets through the unit produces optimized clean slotting and creasing of all corrugated board qualities. This state-of-the-art technology breakthrough for corrugated board conversion represents another EMBA milestone innovation, making Non-Crush Converting™ throughout the EMBA 245 QS Ultima™ machine a reality.

RDD Printer The EMBA RDD – Real Direct Drive servo technology integrates the servo motor with the print cylinder for excellent print register accuracy, also featuring print length and printing plate height compensation. The EMBA top printing concept with space and access between units for pre-mounting of printing plates enables true Quick-Set™ setting of the machine.

APS Folder The Automatic Panel Support (APS) folder with vacuum transport throughout the section contributes to the Non-Crush Converting™ concept. This combination ensures superior folding accuracy, from lightest to heaviest corrugated board qualities and smallest to largest box sizes, for unchallenged productivity.

Counter-Stacker The production of complicated die-cut layouts and high quality printing at top speed is ensured by the Counter- Stacker unit, featuring counting, squaring and stacking of the boxes, performed in a smooth single down stacking motion. This provides the accuracy and reliability required for the outstanding productivity achieved in the EMBA 245 QS Ultima™

EMBA COMFORT

An Investment in the FutureInstallation and commissioning mark only the first steps in a creative and ongoing partnership. When you invest in an EMBA converting inline machine, you invest in the future! With the EMBA Comfort customer support program, you can be certain that your EMBA 245 QS Ultima™ will perform to full capacity throughout its entire life cycle, benefiting from the latest know-how and technical innovations. The EMBA Upgrade Program, featuring the latest technical upgrades from the EMBA research team, makes sure it stays that way.When combined with the EMBA Professional Service Program, production optimization is assured.

The EMBA Original Parts Program is your guarantee that all spare parts supplied are designed for your EMBA 245 QS Ultima™, to the most stringent manufacturing specifications and standards, for trouble-free replacement. Once your production team has completed its EMBA Academy Training, you can rely in the knowledge that your EMBA 245 QS Ultima™ is being operated by EMBA-trained specialists.

The Shape Of Innovation

This overview addresses benefits such as speed, Quick-Set™, flexibility and energy efficiency: all crucial to a healthy bottom line, and all contributing to greater cost-efficiency, environmental sustainability and operator safety. However, the outstanding benefit of EMBA’s new Non-Crush Converting™ technology is improved box performance.

By preserving the geometry of the corrugated profile, EMBA 245 QS Ultima™ technology optimizes paper utilization, producing significant savings in material costs. This redefines operational excellence, reasserting the shape of innovation and securing the future of the ultimate sustainable packaging material: corrugated board.

EMBA 175 QS Ultima™

The progressive evolution of the unique Ultima™ technology platform, combining outstanding production performance with dramatic savings in raw materials and energy. The innovative and patented EMBA Non-Crush Converting™ technology eliminates nip points, preserving the geometry and strength of the corrugated profile throughout the entire converting process, creating significant savings in paper cost with higher BCT values for a much stronger product, while Quick-Set™ enables the shortest possible changeover time between orders.

The intelligent Ultima™ technology platform is born from our desire to constantly exceed market demands and cultivate focused collaboration with our customers. The cleverness of the Ultima™ platform offers “easy to run and easy to learn” features for machine operators and a modular development environment for designers, making the EMBA 175 QS Ultima™ upgrade compatible throughout its entire lifetime. That’s why it’s called Ultima intelligence.

Quick Facts for EMBA 175 QS Ultima™

Board size:

min. 200 x 400

max. 600 x 1700

skip. 800 x 1700

max speed. 500 sh./min. 30,000 sh./h.

EMBA Flexo Folder Gluer 175 QS Ultima

EMBA 215 QS Ultima™

EMBA QS ULTIMA™ is based on the patented Ultima™ platform. EMBA machines combine outstanding productivity, flexibility and material efficiency. The non-crush technology preserves the geometry and strength of the corrugated profile for optimum box performance and significant savings in material costs.

With EMBA 215 QS Ultima™, we are bringing our premium quality solutions to the 2.1 meter converting machine size segment. Powered by the patented UltimaTM platform, designed for high running speeds and outstanding material quality through non-crush technology. The new EMBA 215 QS Ultima™ delivers reliable, high-volume production for your future operations. Inspired by the challenges of our customers, developed for ultimate results.

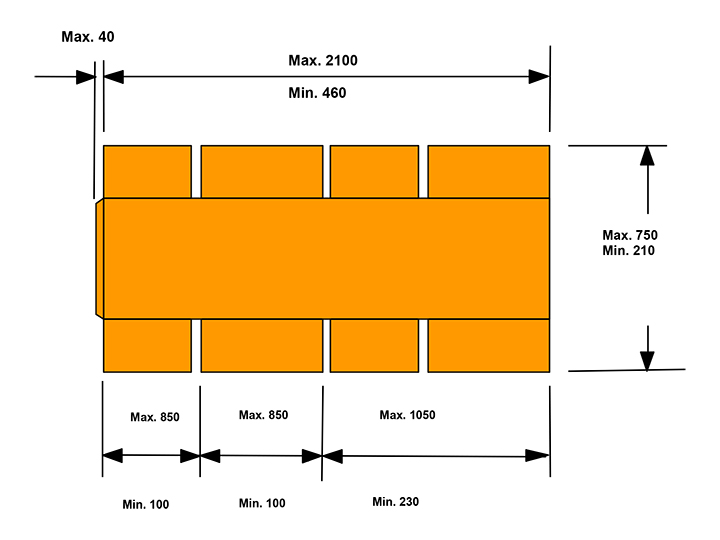

TECHNICAL INFORMATION

| Board caliper: | 1.2 – 8 mm |

| Machine max speed: | 420 sheets/min (25200 sheets/h) |

| Rated el.-power: | 140 kVA (average) |

| El.-power consumption: | 65-80 kVA (normal) |

| Required air pressure: | 650 kPa (6.5 kg/cm2) |

| Air consumption: | 150–400 l/min of free air (normal) |

| Print cylinder diameter: | 258 mm (including printing plates) |

| Max. printing area: | 725 x 2100 mm |

| Unfolded sheets: | max. width 1600 mm |

| Counter stacker - Speed: | max. 28 bundles/min. |

| Counter stacker - Bundle height: | max. 320 mm. |

EMBA 215 QS Box Size Metric

EMBA 245 QS Ultima™

The fully integrated servo platform and modular design of the EMBA 245 QS Ultima™ offers outstanding capacity and flexibility. Fast and cost-efficient, the EMBA 245 QS Ultima™ can produce all types of boxes, from the simplest brown box to the highest quality printing and most complex die-cut formats. The EMBA Operator Interface provides comprehensive control throughout the entire converting process, offering optional interfacing with auxiliary equipment, from pre-feeder to bundling machine and palletizer.

From the high-speed non-crush Ultima Feeder™ to the efficient Counter-Stacker unit, the EMBA 245 QS Ultima™ is optimized for consistent high productivity. High paper utilization, low energy consumption, extreme reliability, minimal waste generation and self-diagnostic capability make it exceptionally cost efficient. And the EMBA Comfort program is your assurance that the EMBA 245 QS Ultima™ will continue to be an excellent investment, throughout its entire life cycle.

Quick Facts for EMBA 245 QS Ultima™

Board size:

min. 280 x 600

max. 1050 x 2450

skip. 1400 x 2450

max speed. 300 sh./min. 18,000 sh./h.EMBA’s true patented Non-Crush Converting™ technology preserves the geometry and strength of the corrugated profile for optimum box performance and significant savings in material costs.

EMBA Flexo Folder Gluer 245 QS Ultima